Textile Computing and Waste Recycling Goes Digital

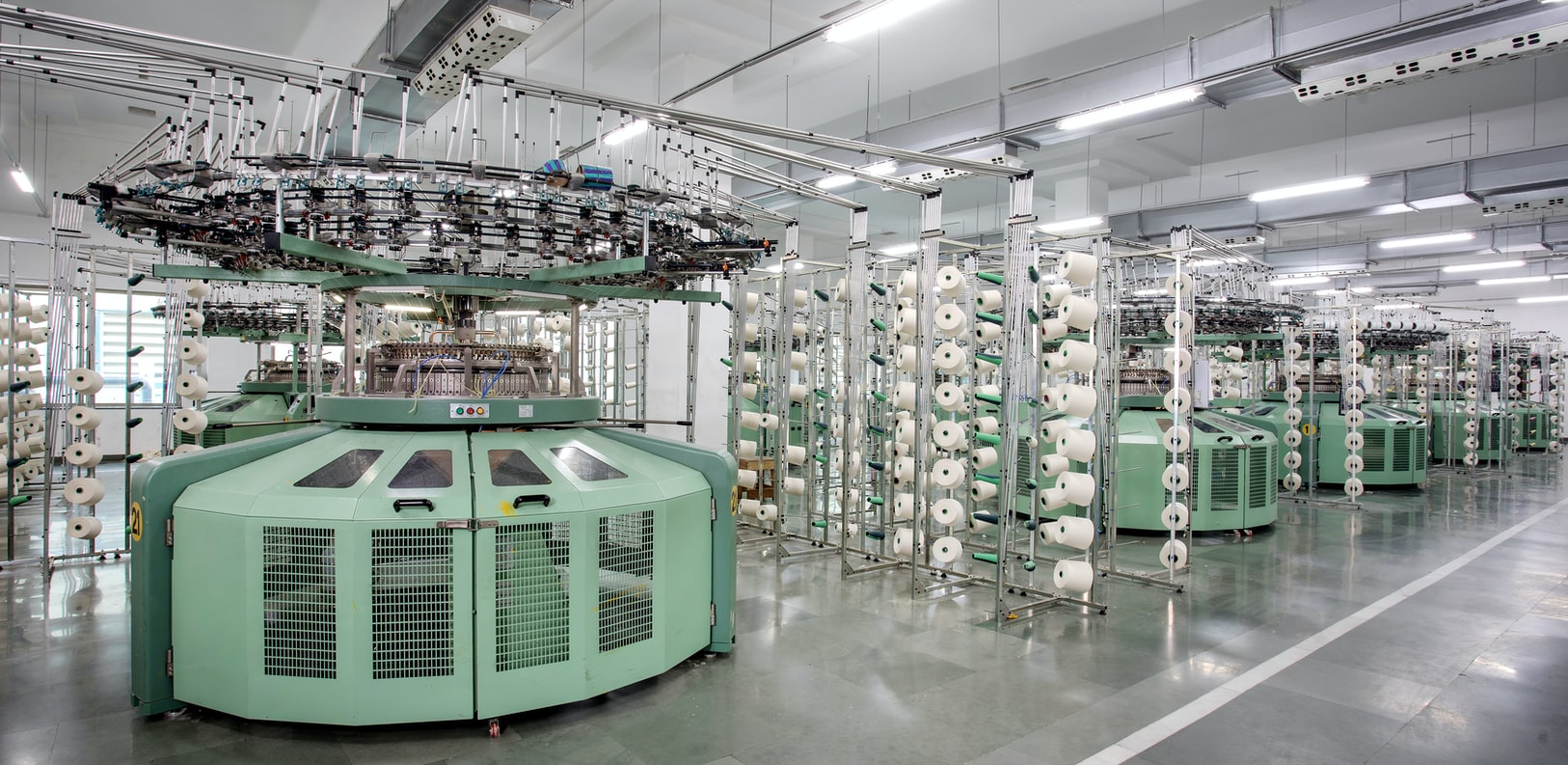

Tubular Knitted Fabric Machine. Credit: Lalit Kumar on Unsplash

Tubular Knitted Fabric Machine. Credit: Lalit Kumar on Unsplash

Acoustic Monitoring

Assembly Line

Detect: Monitoring, Identifying, and Responding to Industrial Cyber Threats

A harsh reality of cybersecurity is that even the most state-of-the art protective controls cannot fully eliminate risk. As such, the ability to detect, investigate, and respond to potential threats quickly and effectively when they do surface is imperative.

The purpose of detecting threats is to mitigate those which pose risk to your organization. But to determine which threats to focus on, your team needs the ability to make sense of what’s being detected within your organization’s industrial environment. This is another area where the sheer size and complexity of enterprise industrial networks comes into play; without the right capabilities in place, security personnel can be flooded with an overwhelming barrage of alerts that do little to inform risk-mitigation decisions.

Going Glocal: What is Glocality and How Can Cloud Manufacturing Help?

Glocalization is a combination of the words “globalization” and “localization.” It is used to describe a service or product that is made and distributed globally, but adjusted to better accommodate the customer in a local market. For manufacturing, it is when global hardware companies produce locally to better meet demand.

IIoT builds new bridges to new adventures

Engenuity Inc. in Conroe, Tex., provides control automation and data integration for oil and gas and other industries, and recently found deficiencies in validation pressure testing of blowout preventers (BOP) and well-control devices. Because pressure tests are needed every few weeks for regulatory compliance, executed and recorded manually over several hours, and can cost up to $6 per second to run in offshore valve arrays, testing can cost millions of dollars per year. To reduce these expenses, Engenuity collaborated with clients like Shell International Exploration and Production Co., and developed automated, hydrostatic, test execution and reporting solutions, which use Opto 22’s groov Edge Programmable Industrial Controller (EPIC) for process control, automatic notification, and process history storage and replication.

Smart Textile Manufacturer Profile: Myant, Inc.

Founded in 2011, Myant develops smart textiles that are revolutionizing the textile industry for the healthcare and consumer markets. Myant not only challenges the norms of the industry but also collaborates with other innovative start ups, manufacturers, and research institutes in Ontario to build an entirely new ecosystem around smart textiles.

Textile Computing, as Myant defines it, is the technology that connects the human body to the world around it through textiles. Capitalizing on the latest advances in various disciplines, the 10-year old Toronto-based start up knits everyday textiles out of conductive yarns and embeds biometric sensors and actuators into them. A proprietary software platform records and processes the data collected through the hardware, giving Myant’s products the ability to sense and react to the human body.

Visual Inspection AI: a purpose-built solution for faster, more accurate quality control

The Google Cloud Visual Inspection AI solution automates visual inspection tasks using a set of AI and computer vision technologies that enable manufacturers to transform quality control processes by automatically detecting product defects.

We built Visual Inspection AI to meet the needs of quality, test, manufacturing, and process engineers who are experts in their domain, but not in AI. By combining ease of use with a focus on priority uses cases, customers are realizing significant benefits compared to general purpose machine learning (ML) approaches.

Surge Demand

Avery Denison clothing gets digital care labels for textile circularity, enabling regenerative yarns with Ambercycle. TechSee uses AI and augmented reality to help you service assets. NVIDIA opens beta access to Isaac Sim on Omniverse.